Hotline

0903 999 763List products

Producer

Utilities

Rosemount Vortex Flowmeters allow you to achieve better measurement practices across your applications by eliminating potential leak points, incorporating gasket-free meter body designs that are immune to vibration, and enabling best installation practices with the Reducer™ Vortex

|

|

Rosemount 8800 Series Vortex Flowmeter Rosemount Vortex Flowmeters allow you to achieve better measurement practices across your applications by eliminating potential leak points, incorporating gasket-free meter body designs that are immune to vibration, and enabling best installation practices with Reducer™ and MultiVariable™ Vortex. Reducer™ Vortex can save up to 40% per installation by eliminating the need for field installed reducers. MultiVariable™ Vortex can save up to 30% per installation by eliminating the need for external temperature compensation for saturated steam applications. See for yourself how the Rosemount 8800 Vortex Flowmeter can solve your flow challenges. |

|

|

Rosemount 8800 CriticalProcess™ Vortex Flowmeter The Rosemount CriticalProcess™ Vortex is designed to increase plant availability and enhance overall safety. This feature allows users to verify the performance of the Vortex sensor while providing an added level of safety on critical applications. The CriticalProcess™ Vortex provides:

The Vortex sensor in the Rosemount 8800D Vortex Flowmeter is isolated from the process making it possible to maintain the performance of the sensor online, greatly increasing process availability. Sensor maintenance can be costly with traditional Vortex flowmeters. Unlike the 8800D, wetted Vortex sensor designs require that the process be shutdown or the meter bypassed to perform Vortex sensor maintenance. The CriticalProcess™ Vortex eliminates this requirement, increasing availability and enhancing overall safety. |

|

|

Rosemount 8800 Reducer™ Vortex Flowmeter for Low Volume Flow Rosemount Vortex Flowmeters allow you to achieve better measurement practices across your applications by eliminating potential leak points, incorporating gasket-free meter body designs that are immune to vibration, and enabling best installation practices with the Reducer™ Vortex By building the reducers into the meter, the Reducer Vortex can measure lower flows than any other Vortex meter. The benefit is simplified installations which reduce project risk andminimize installation costs. The face-to-face dimensions of the 8800 Reducer Vortex match that of the 8800 Traditional Vortex. As estimated process conditions change during projects you can switch between the Reducer Vortex and 8800 Traditional Vortex with no piping changes. |

|

|

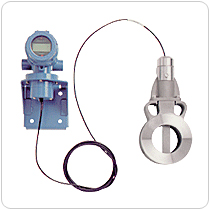

Rosemount 8800 MultiVariable™ Vortex Flowmeter The Rosemount 8800 Multivariable Vortex Flowmeter combines your temperature and flow devices into a single, highly accurate instrument, eliminating the costly installation of two separate devices. And with its non-wetted sensor design, shutdowns for maintenance or repair aren’t even an issue. MultiVariable™ Vortex can save up to 30% per installation by eliminating the need for external temperature compensation for saturated steam applications.

|